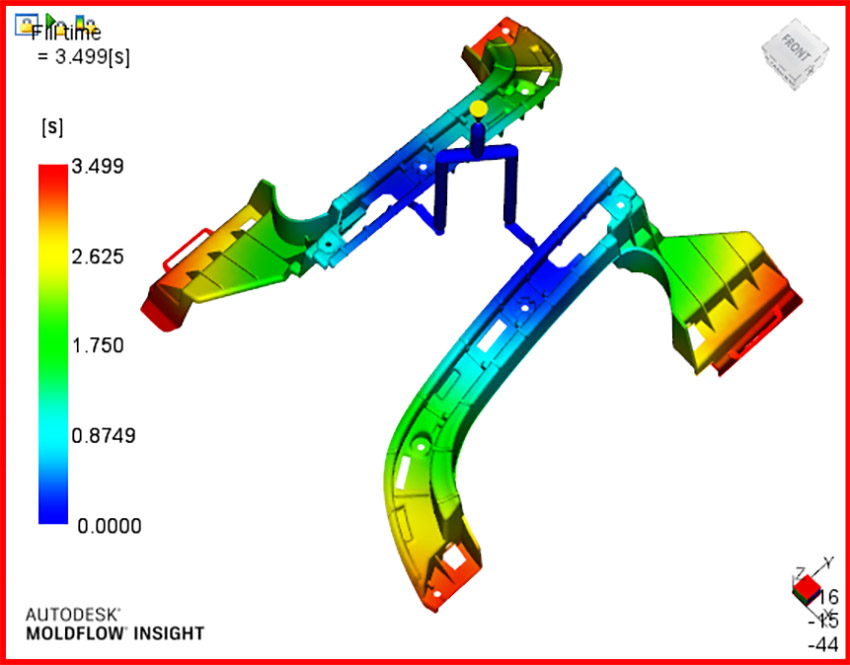

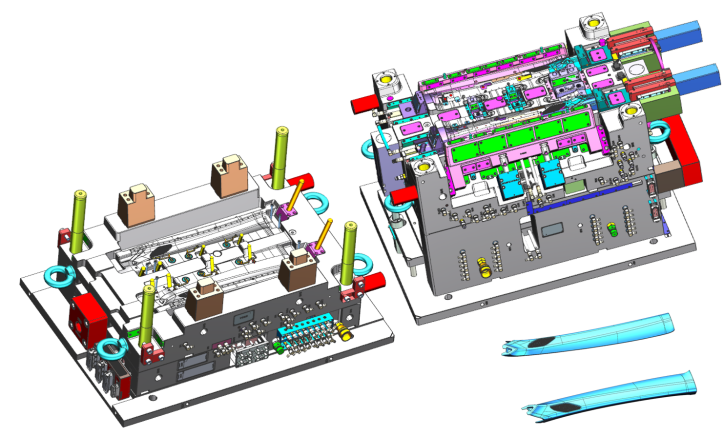

Mold flow software provides simulation tools for injection mold design, plastic part design, and the injection molding design process.

ZC has been utilizing Mold Flow,Mold Flow is an essential element of any injection molding design project.

Mold filling simulation allows for verifying part design before mold tool steel is ever cut ensuring that major revisions will not be necessary to either the part or the molds.

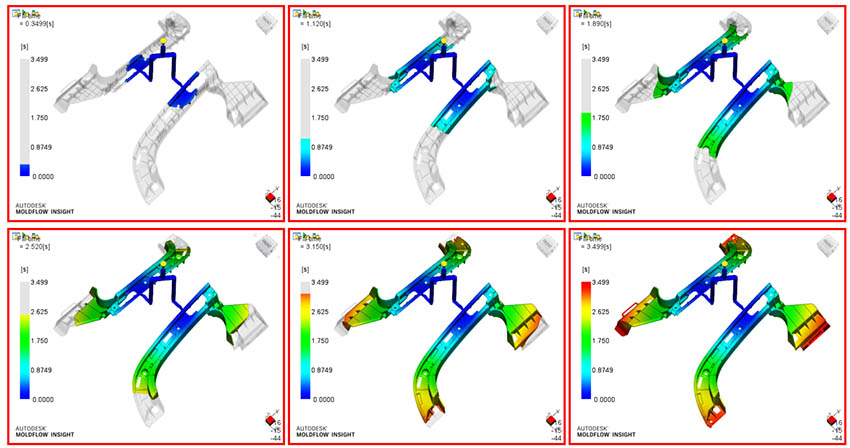

It simulates the flow of the plastic melt into the mold cavity and provides results that will help part designers, mold designers, and injection molding manufacturers validate and optimize their products.

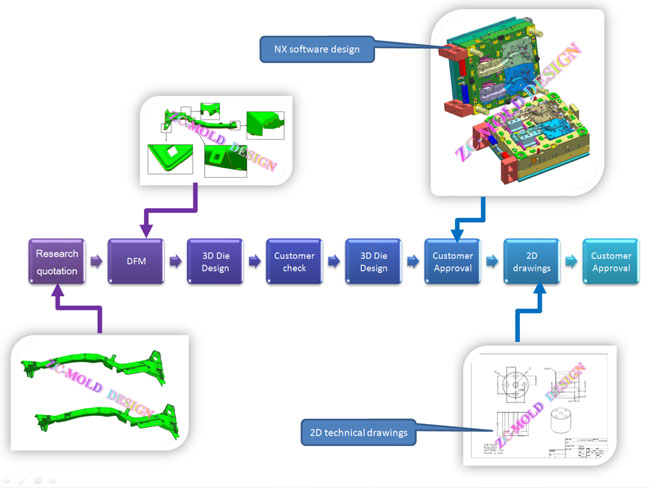

What we provide on Mold Flow project:

l Runner/Gate Sizing

l Material selection

l Filling pattern

l Injection pressure

l Pressure at injection location

l Clamp force

l Sink marks estimate

l Air traps

l Weld lines

l Warpage effect

Our Mold Flow analysis is planned to decrease design and production errors through in-depth CAE mold flow analysis which gives important data to guarantee consistent product specifications, long lasting molds & tooling, and the highest possible product quality.