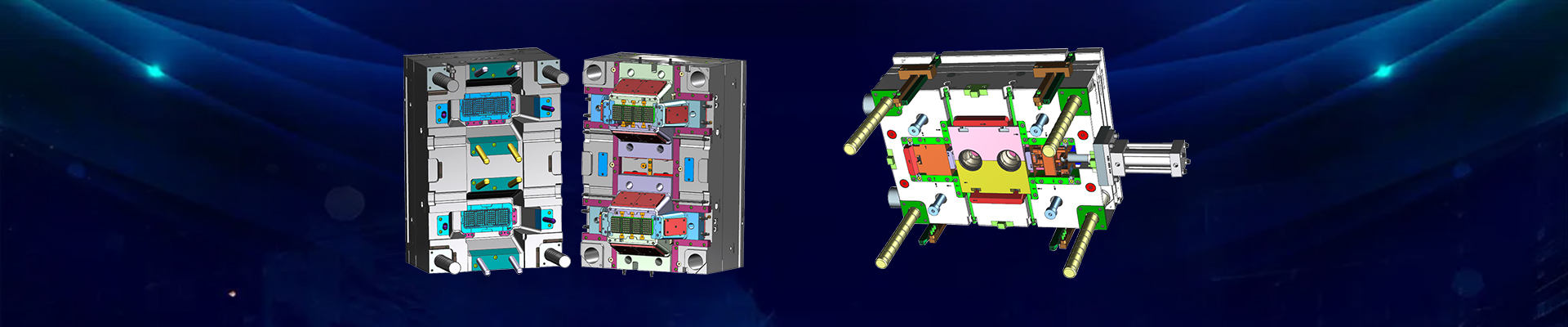

NX software delivers a state of the art solution that enables mold manufacturers to shrink their lead times and tighten their cost controls. By combining industry knowledge and best practices with process automation, NX Mold Design streamlines the entire mold development process: from part design to tool assembly layout, tool design and tool validation. NX Mold Design excels at even the most challenging mold designs, providing advanced functionality, step by step guidance and associativity with part designs to ensure fast response to design changes and quality molds.

NX UG Mold Design-Product analysis

Import part geometry and drawings using data translators. Easily model and perform design changes to ensure desired design intent and achieve manufacturability.

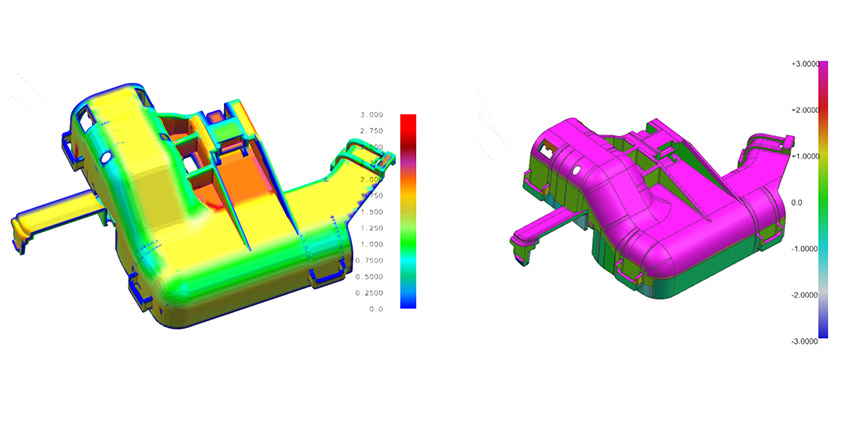

1. We can use wall thickness checking functions to analyze the wall thickness of plastic and cast. Fox example, in picture 1, we can check out the red area where the wall thickness of plastic is thick, we should pay attention to whether there is a risk of shrinkage in the red area, and we can better evaluate the feasibility of the product to change the product.

2.We can use slope analysis to check if there is a draft angle in this model.The draft angle analysis of the product is beneficial to the better mold release of the product in the mold.

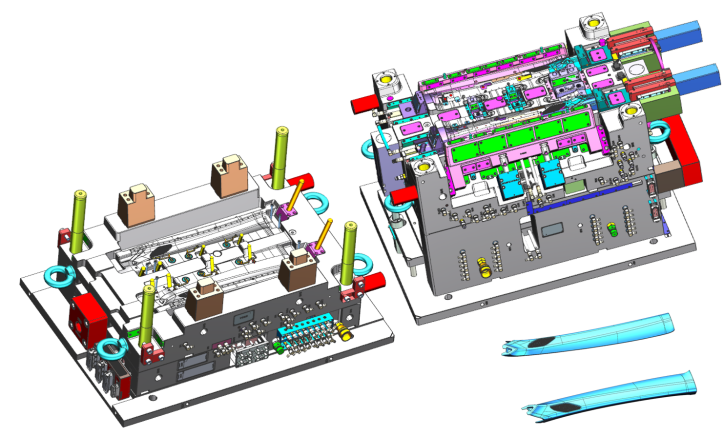

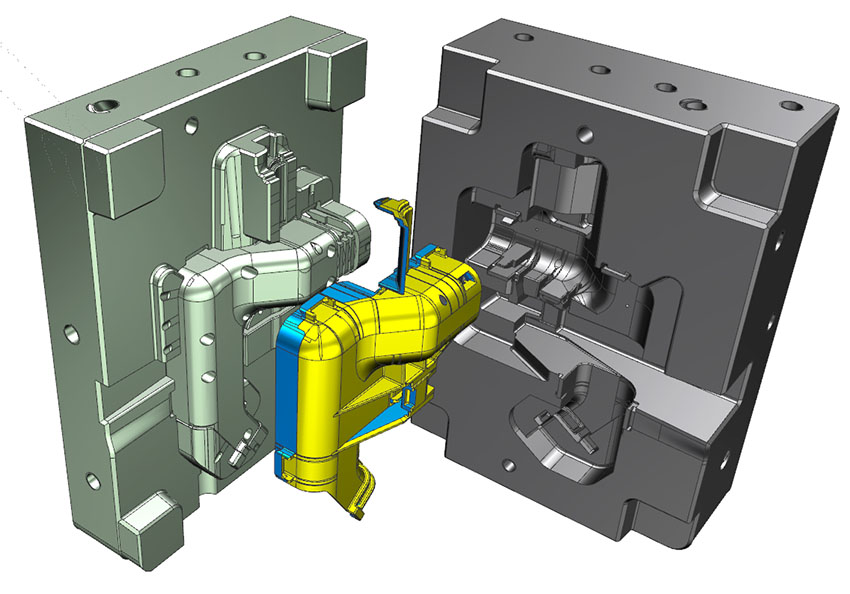

NX UG Mold Design-Create the Core and cavity

Core cavity development Automate shut offs and parting of core/cavity based on manufacturability considerations.Performs region analysis using visibility of the cavity and core sides, defines the position of the cavity and core sides, creates a parting surface according to the parting line and separates a solid to get the cavity and core.

Slope Analysis Visualizes the angle between the surface normal at all points on a surface and a plane that is normal to a reference vector. Slope analysis is particularly useful for the mold designer.We need to use the Slope Analysis function to check whether there is undercut, the angle is in the cavity and core side.

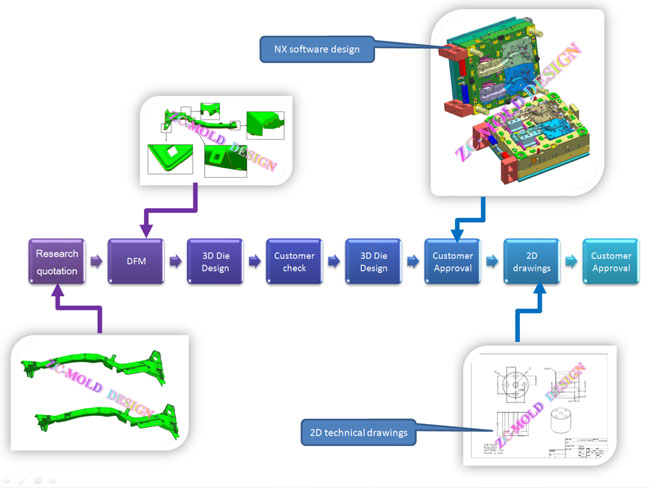

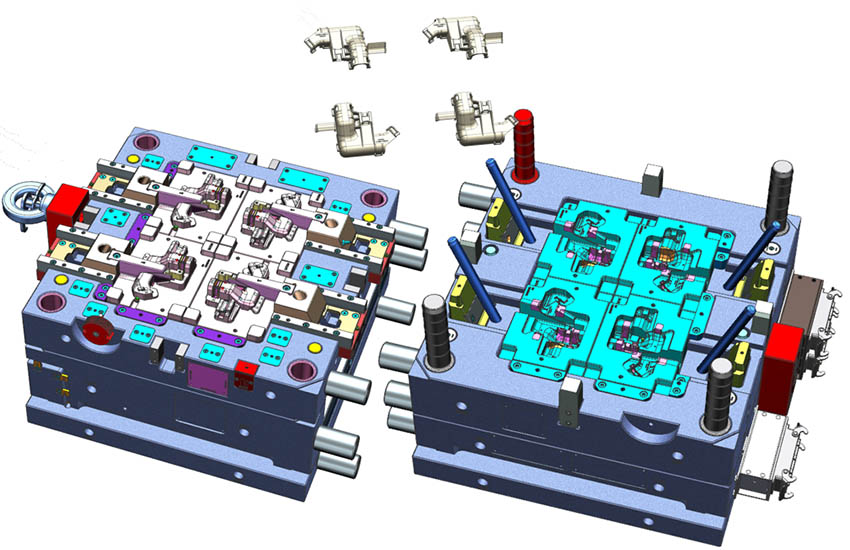

NX UG Mold Design-Mold Structure

Layout the core, cavity, component systems, and mold base for both prototype and production-scale multi-cavity molds. Configure the mold using libraries of standard parts, component systems, and mold bases. You can design associative sliders and lifters. Quickly add and trim ejector pins and insert cooling channels with parametric patterns. Include runners, gates, screws, pins, and other standard components.

NX Mold Design content

l Shrinkage

l Parting line and surfaces

l Shut-off surfaces

l Core/cavity and region split

l Cooling

l Merge cavities

l Machining

l Tool validation

l Tool design

l Tool layout

l Runners and gates

l Subinserts and hole charting

l Sliders

l lifters

l Ejection

l Concept design

l charting

l Design change control