Committed to promoting the vigorous development of mold design industry

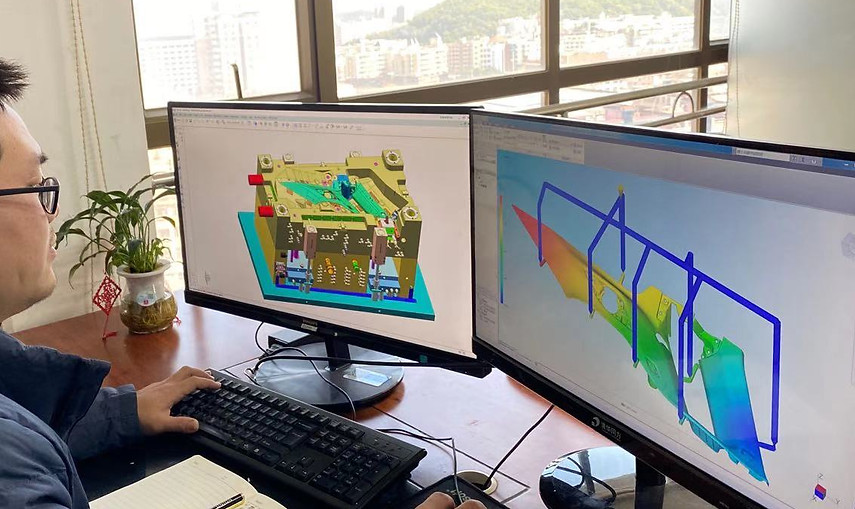

Moldflow software provides simulation tools for injection mo...

We have been providing mold design for United States(Britain...

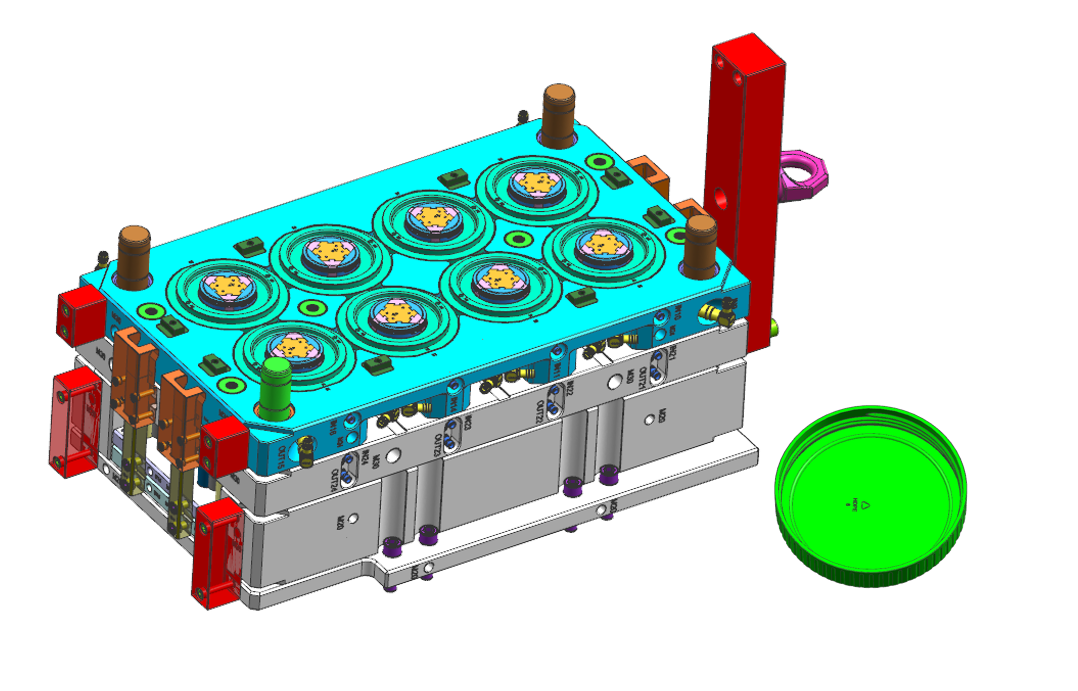

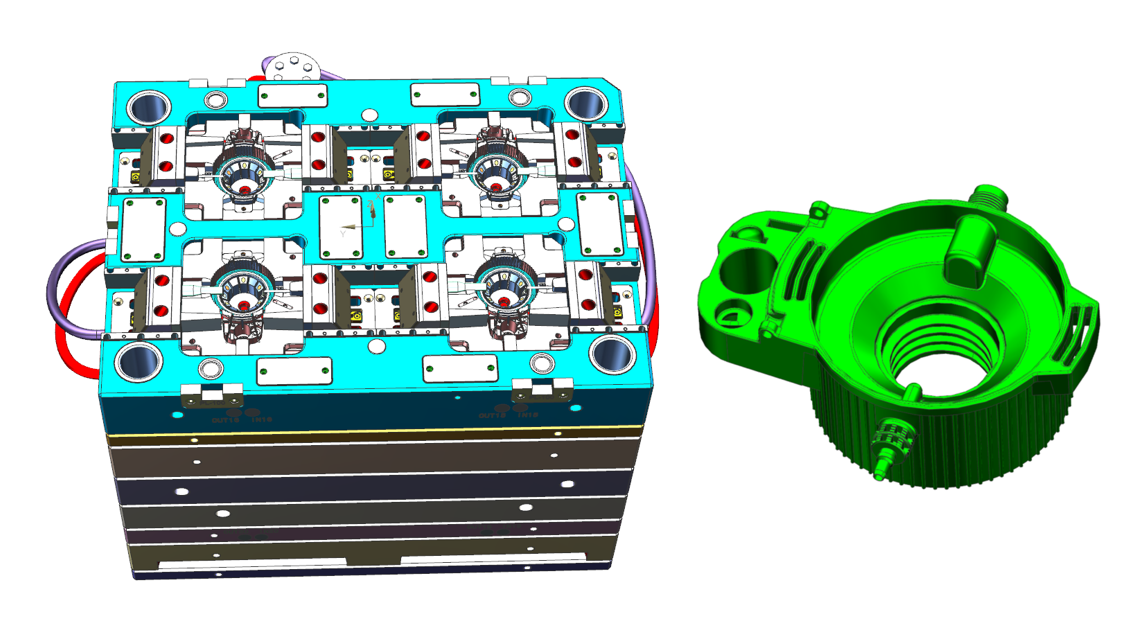

Collapsible Core can be used for threaded features. The mold...

The inside small slide block will recede first and the paren...

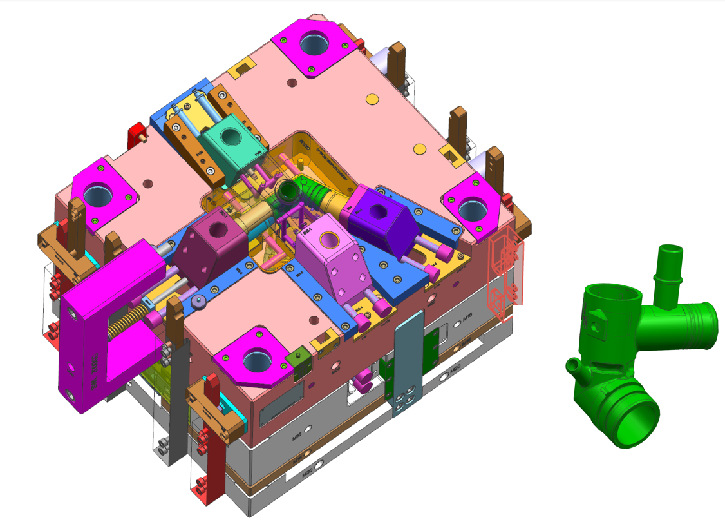

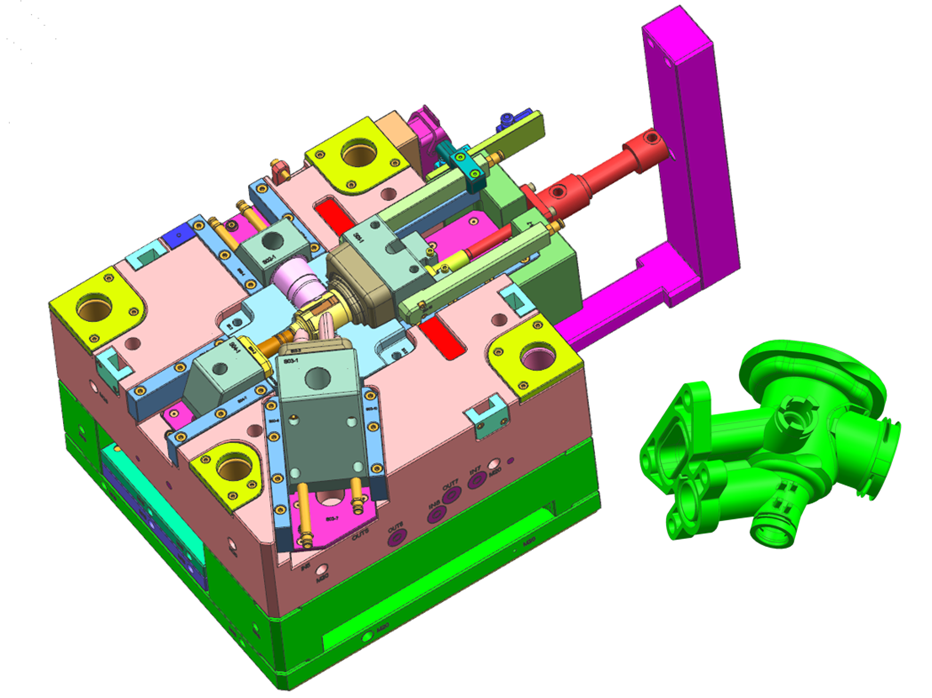

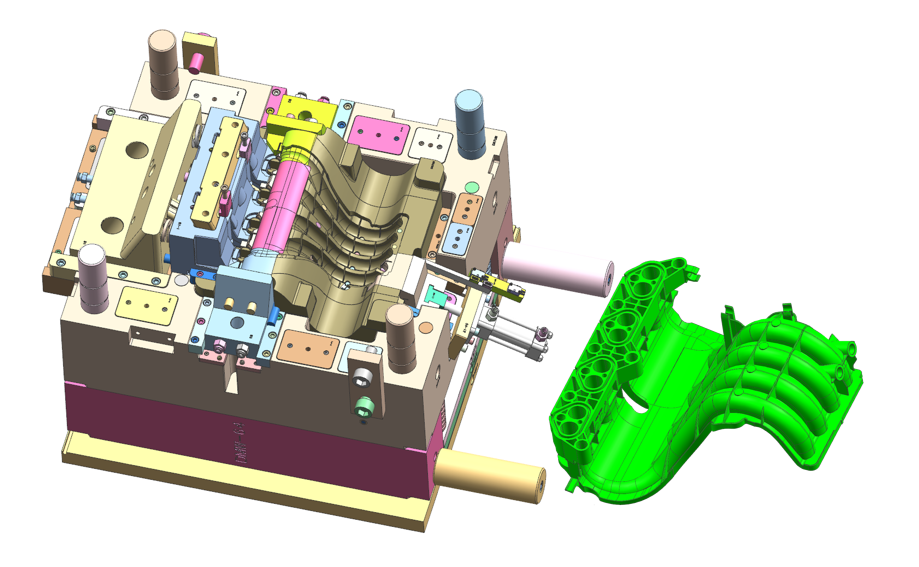

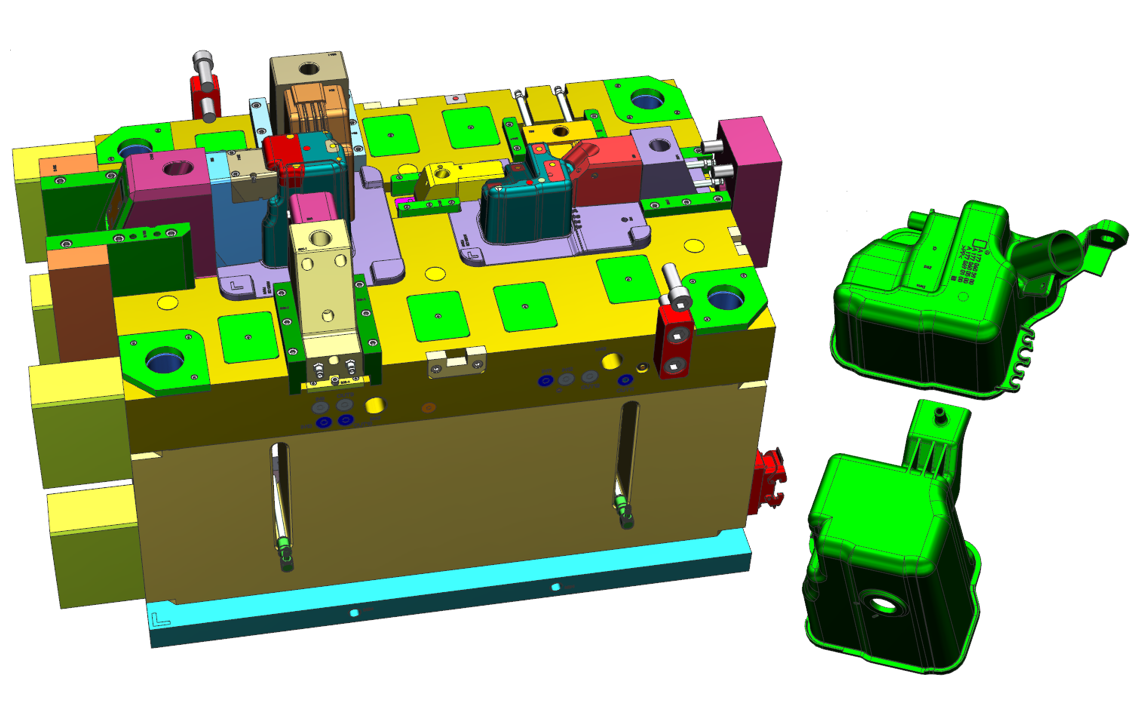

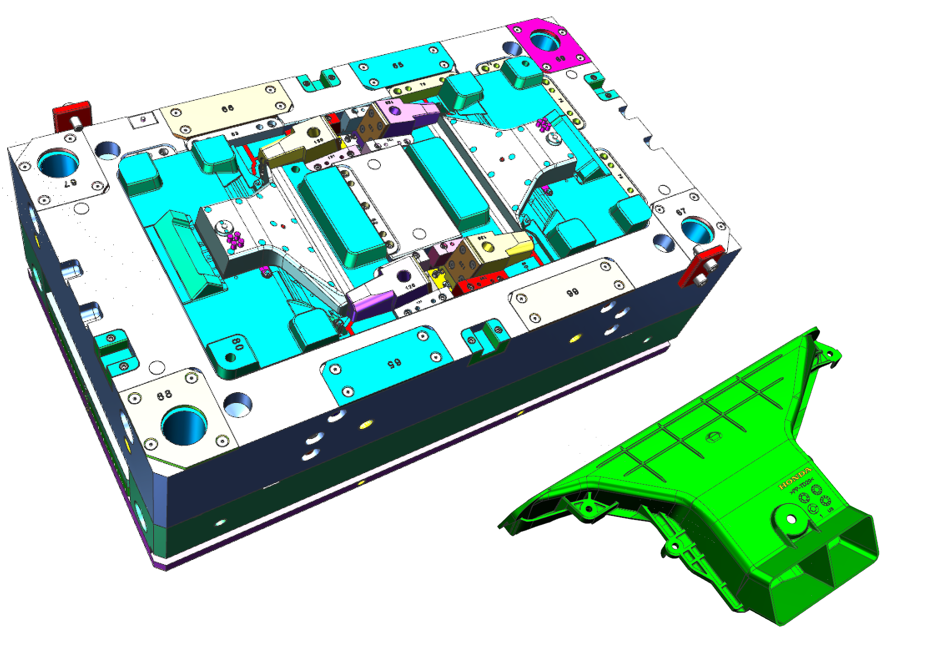

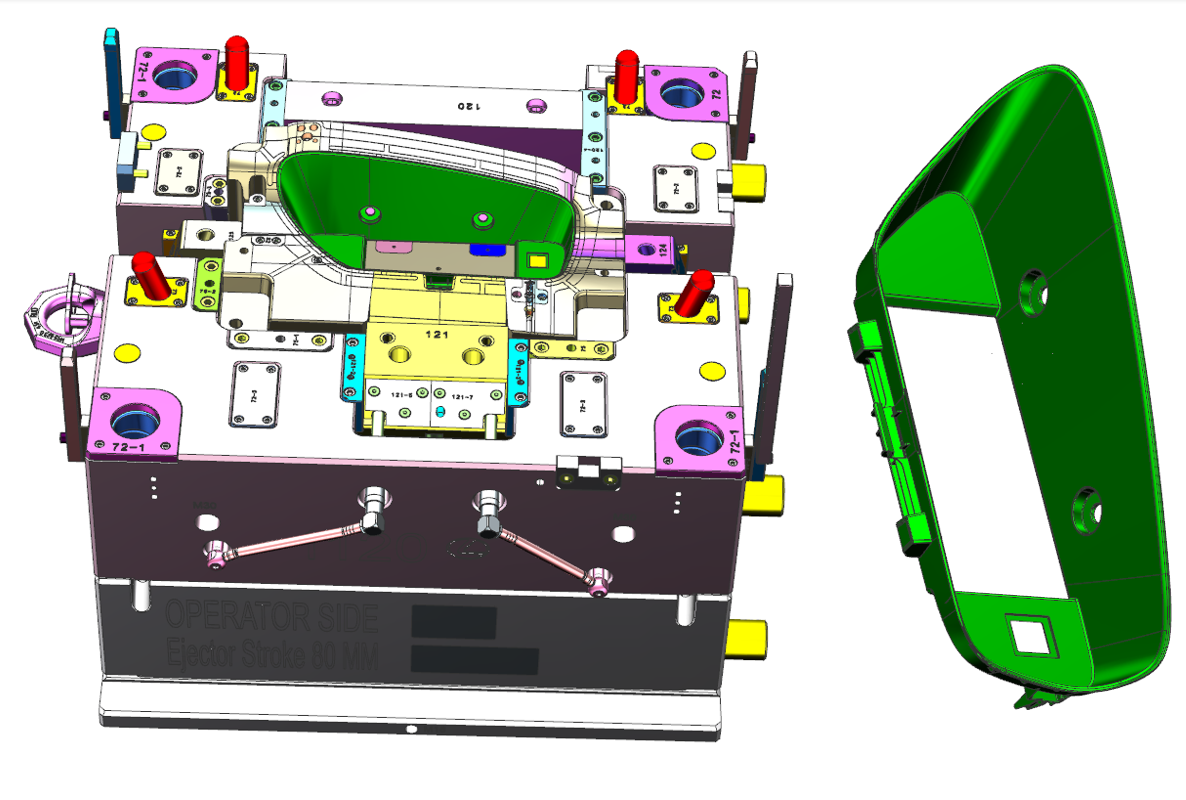

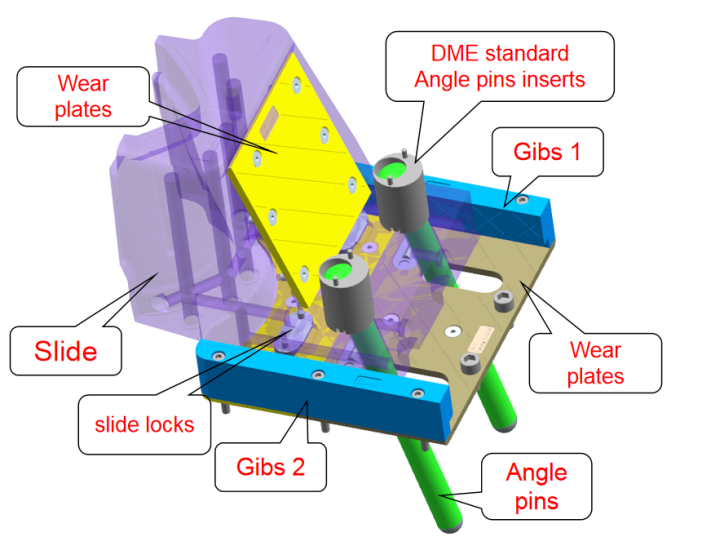

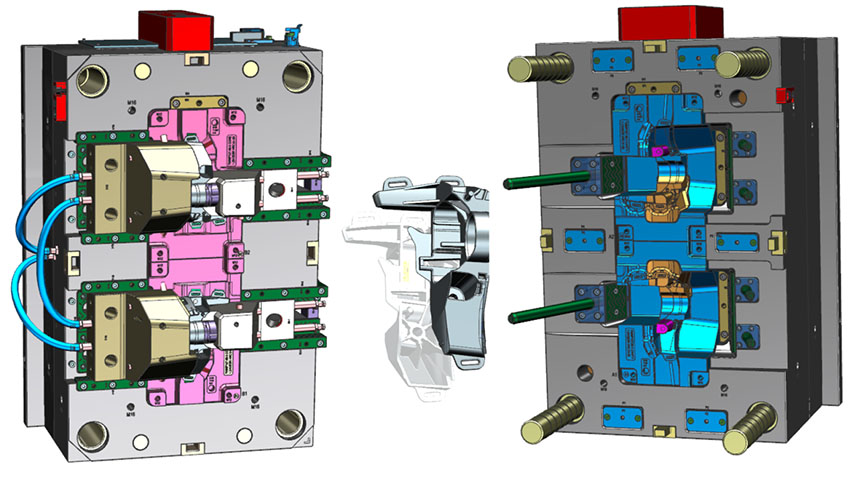

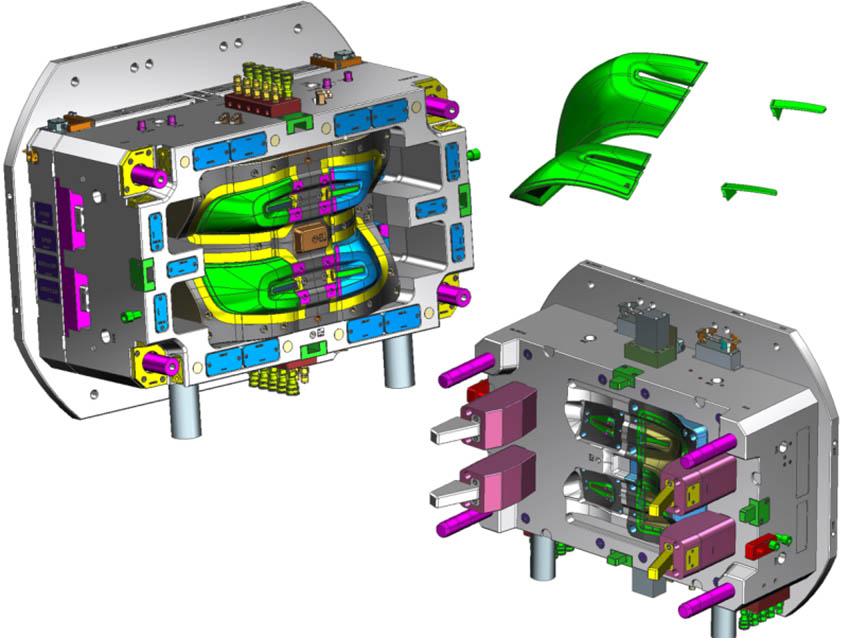

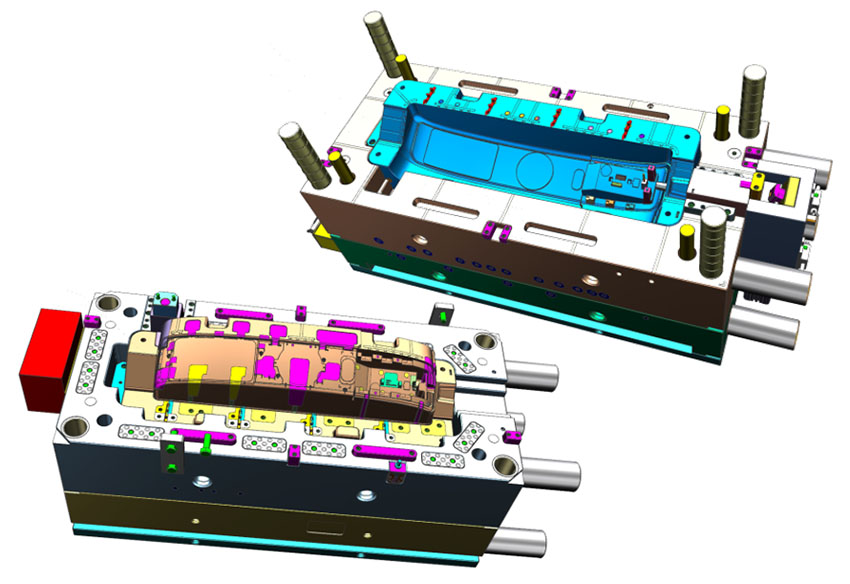

Mold design of complex slide structure

All slide designs/type are determined by the part shape.Mech...

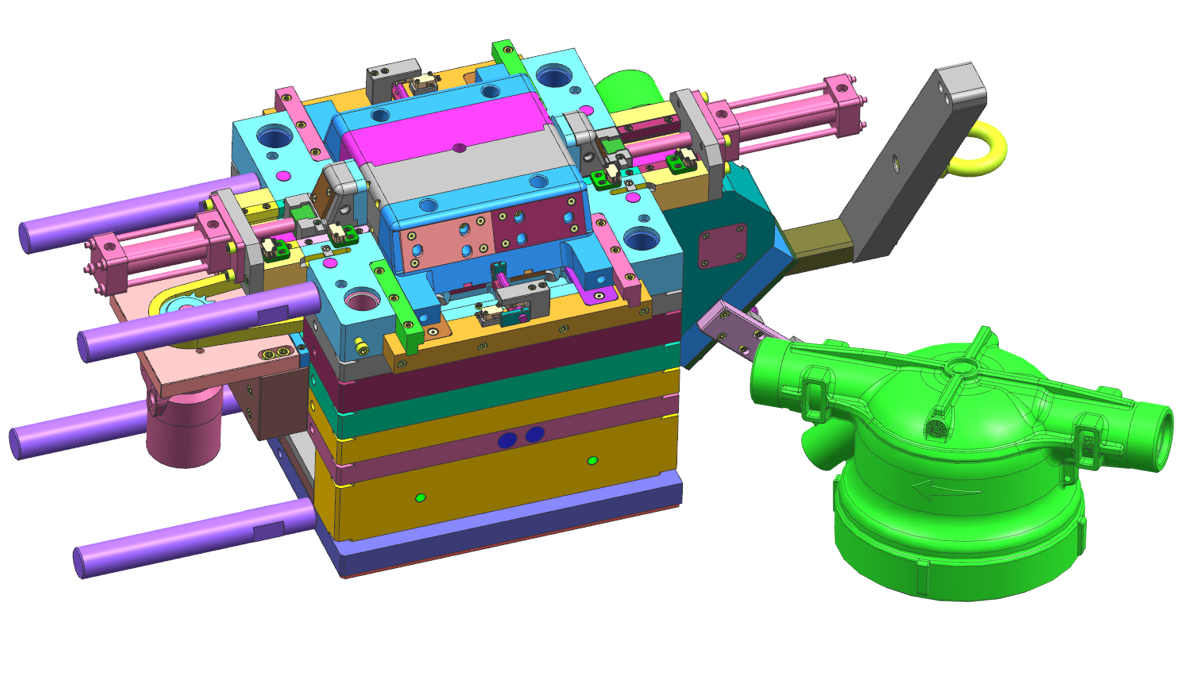

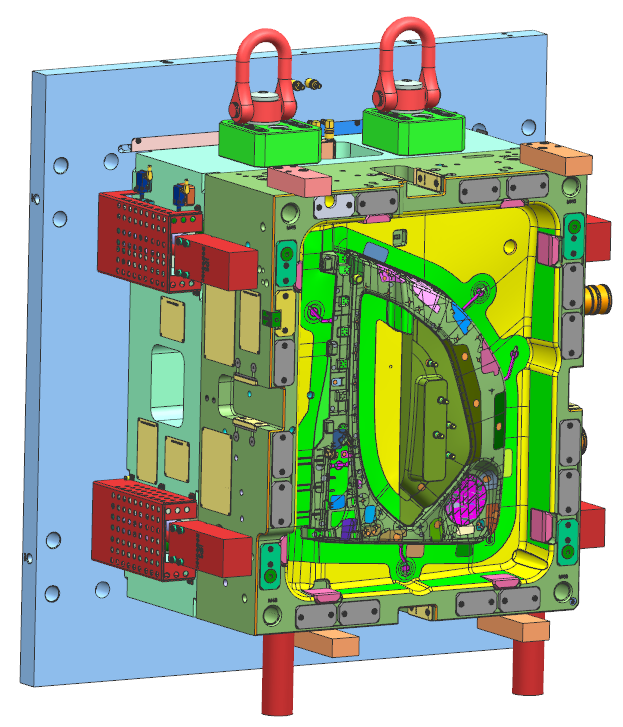

What type of mold design have you done?ZC has designed many ...

1.DFM can better assist you in mold design,2.Understand cust...

ZC is a comprehensive design company incorporating mold desi...

In the United States,always design with English units, not m...

All slide designs/type are determined by the part shape.Mech...

2021-12-29What type of mold design have you done?ZC has designed many ...

2022-08-221.DFM can better assist you in mold design,2.Understand cust...

2022-08-24ZC is a comprehensive design company incorporating mold desi...

2022-08-24Shenzhen Zhongcheng Chuanghe Technology Co., Ltd. is a comprehensive design company integrating mold design, product design, and mold flow analysis. It aims to provide professional mold design and product design technical services for domestic and foreign mold manufacturers, plastic injection molding companies, industrial design companies, and traders.

We currently employ 9 designers, most of whom have actual tool shop experience. This experience gives our designers a “real world” concept of mold making and the information necessary for quality designs. We design to our customers’ standards and specifications in conjunction with our own internal processes and procedures to ensure every design meets or exceeds our customers’ expectations

Shenzhen Zhongcheng Chuanghe Technology Co., Ltd. has a unique combination of decades of mold design experience with the latest CAD technologies and offers a fast track program to get your 2D/3D mold designed in the fewest days.

We not only satisfy your demands as your supplier but also we energetically look for methods to optimize your mold structure, therefore, save your cost and time during a long period of massive production. We have good quality management techniques that are so successful.

the most professional mold design company and mold design manufacturer in China

Baixi Rd, Heshuikou, Guangming New District, Shenzhen, China

Powered by Shenzhen Zhongcheng Chuanghe Technology Co., Ltd.